Introduction

Helium is a fascinating element that has numerous uses in industry, healthcare, and leisure. It is non-toxic, non-flammable, and has a much lower density than air, making it perfect for inflating balloons and airships, cooling MRI machines, and welding aluminum. However, helium is a rare gas and the only way to obtain it is through extraction from natural gas or by creating it artificially. In this article, we will explore the chemical and physical processes that make up helium and discuss the various ways to produce it, from DIY to industrial production.

Chemical Process

Helium is the second element on the periodic table and has two protons in its atomic nucleus. It is the lightest noble gas and is colorless, odorless, and tasteless. Helium is formed in the universe through nuclear fusion, a process that occurs when two atomic nuclei come together and create a heavier nucleus. In the sun, the nuclear fusion of hydrogen atoms produces helium, releasing a tremendous amount of energy in the process. Once helium is formed, it rises to the surface of the sun and is released into space.

Physics of Gas Formation

Gas laws and thermodynamics govern the physical processes involved in the formation of helium in stars. As nuclear fusion occurs, the temperature and pressure inside the star increase, causing the gas to expand and cool. This process is known as adiabatic cooling and is responsible for the formation of helium in stars. In the earth’s crust, helium is produced through the radioactive decay of uranium and thorium, which release alpha particles that can combine to form helium nuclei.

Extraction from Natural Gas

Natural gas is the primary source of helium on Earth, and it is found in only a few select locations. Helium is usually found in small concentrations of less than 1%, so specialized techniques are required to extract it. Cryogenic processing and adsorption are the two main methods used to extract helium from natural gas. Cryogenic processing involves cooling the natural gas to -269°C (-452°F) to separate it from other gases. Adsorption uses a solid material to trap helium and then release it through warming. After extraction, the helium must be refined and stored for commercial use.

DIY Balloon Inflation

If you’re looking for a more lighthearted approach to producing helium, you can try your hand at DIY balloon inflation. To make helium at home, you will need a compressed gas cylinder, balloon valves, and a balloon regulator. Safety should be your top priority during this process, so make sure to use gloves and eye protection, and follow all instructions carefully. Once you have your equipment set up, you can begin inflating your balloons with homemade helium.

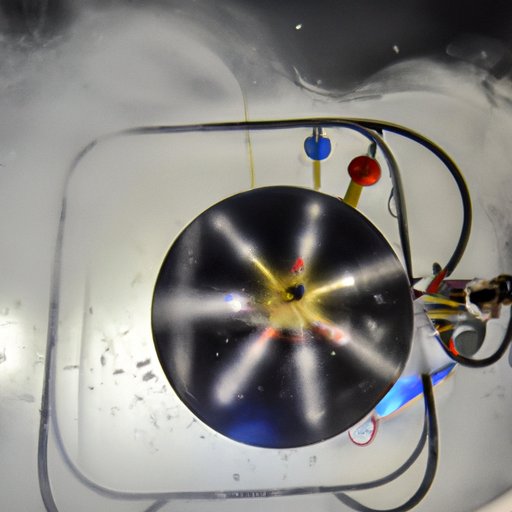

Industrial Production

Industrial production of helium involves liquefaction and pressurization techniques. Larger plants are required to handle the massive volumes of natural gas that need to be processed to extract helium. Once the helium has been extracted, it is liquefied and transported through pipelines or stored in pressurized containers. Helium has numerous commercial uses, including in welding, electronics, and healthcare. It is also used in cryogenics to cool magnets and other scientific equipment.

Future Technologies

Scientists are constantly exploring new ways to produce helium, and emerging technologies offer some exciting possibilities. Fusion reactions offer a way to create helium artificially, using materials like deuterium and tritium. Materials that can trap helium are also being developed, providing a way to extract helium from the atmosphere and other sources. With the increasing demand for helium and the limited supply, these new technologies offer a more sustainable path forward for its production and use.

Conclusion

Helium is a remarkable element that has many important uses in our daily lives. Its limited supply and continued demand make it essential to explore alternative methods of production. Whether you’re inflating balloons at a party or cooling scientific equipment, understanding the different methods of helium production can help reduce waste and ensure a steady supply for years to come.